Saudi Arabian Fertilizer Co (Safco) a subsidiary of the Saudi Basic Industries Corporation Sabic, announced on January 2011 that it had abandoned plans to build a steel plant at Jubail and would instead study a long-awaited urea project, through a feasibility study for a new 1.1m tonnes/year urea plant, called Safco V. The plant would use surplus ammonia generated by existing Saudi plants and gas feedstock has been agreed by the Ministry of Petroleum and Mineral Resources. The urea complex is expected to be completed in the second half of 2013. Safco produces ammonia, urea, sulphuric acid, and melamine and uses them to manufacture fertilizers, and Sabic manufactures chemicals and steel and is the world’s largest petrochemical maker.

India: RCF Expansion Plans

February 17, 2011 at 11:09 (Fertilizers, Nitrogenous Fertilizers)

Mumbai based Rashtriya Chemicals and Fertilizers Limited (RCF) will revamp the Thal plant to increase its capacity from 1.7 to 2 million tonnes by setting up an ammonia-urea stream for production of 1.15 million tonnes of additional urea. The Thal plant was commissioned in 1985 and the ammonia stripping process is licensed by Snam-Progetti. In addition, RCF, along with GAIL and Coal India Limited, is actively pursuing the setting up of an ammonia-urea project at Talcher in Orissa through the coal gasification route. Besides this domestic expansion schemes, they are also exploring possibilities of setting up an ammonia-urea project at Ghana based on natural gas and another one in Indonesia based on coal gasification. RCF, India’s biggest state-run urea maker, has two manufacturing units located at Trombay and Thal and a marketing network throughout the country. Their main discharge port is Mumbai, on India’s west coast. Besides urea and complex fertilisers, RCF also produces bio-fertilizers, micronutrients and 100% water soluble fertilizers.

Brazil: Vale plans to become one of the main global players in the fertilizer market

February 17, 2011 at 10:22 (Fertilizers)

Brazil’s Vale SA, the world’s biggest iron-ore producer and second- largest nickel miner, has a strategy of diversify from iron ore and becoming one of the world’s main fertilizer producers by 2017 by tripling their fertilizer production to some 25 million tonnes. This is driven by a 3.8% demand increase in the Brazilian food needs. They plan to invest during the current year $2.5 billion in the fertilizer business, of which, almost half is geared to the Rio Colorado potash project in Argentina.

USA: Innophos expands industrial phosphate capacities

February 17, 2011 at 10:19 (Industrial News, Industrial Phosphates)

New Jersey headquartered Innophos Holdings, Inc., the largest specialty phosphates producer in North America, has completed the expansion for the production of potassium phosphates at its Port Maitland, Ontario facility. These specialty products provide unique functionality for the meat and dairy industries and also have applications in industrial markets including water treatment and industrial cleaners.

At its Chicago Heights, IL facility, the Company announced plans for a 25% increase in tri-calcium phosphate capacity. This product is used throughout the food industry and has seen significant increase in demand particularly in the beverage and dairy segments. This expansion uses new process technology which achieves a significant improvement in throughput and a broader product range by optimizing existing production lines at Chicago Heights. The expansion is expected to be completed by mid year 2011.

Innophos net sales for 2010 were $714 million, a 7% increase over 2009 on 21% volume growth.

France: GPN transfers its Mazingarbe TAN plant to Maxam

February 17, 2011 at 10:17 (Industrial News)

French nitrogenous fertilizer maker GPN, a subsidiary of oil giant Total, is tranfering its industrial ammonium nitrate business to the Spanish Maxam, which is the world second largest manufacturer of civil explosives. The TAN plant is located at Mazingarbe, northwest France. Maxam already operates in France, in Selles-Saint-Denis where it produces civil explosives and through a joint venture with SNPE (Société Nationale des Poudres et des Explosifs) in Bergerac producing nitrocellulose. Maxam operates in some forty countries and 75% of its turnover comes from the production of civil explosives. Maxam sales around the world were of approximately 900M€ in 2010. The use of explosives in mining and public works not only reduces the time and cost of operations, but also allows the correct amount of energy to be used, thus saving hydrocarbons and reducing greenhouse gas emissions compared with the use of mechanical means such as borers, grinders, tunnelling machines, etc.

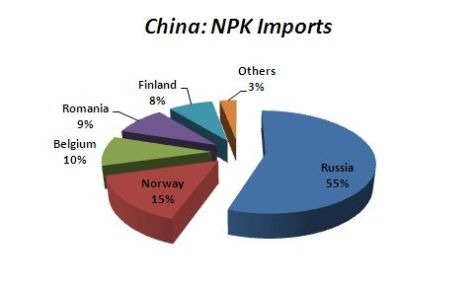

China: NPK Imports

February 17, 2011 at 10:09 (Fertilizers)

Indonesia: NPK j-v with Jordan

February 17, 2011 at 09:50 (Fertilizers, Nitrogenous Fertilizers, Phosphate Fertilizers)

PT Pupuk Sriwijaya Palembang and Jordan Phosphate Mine Co. Ltd. (JPMC) have agreed on a cooperation plan to develop a company that will produce phosphoric acid, sulphuric acid, as well as NPK fertilizer. The factory will be located in Gresik of East Java province. The project will be carried out in 2012 to 2015 and it consists of facilities with a nameplate capacity of 0.2 million tonnes phosphoric acid per year, 0.8 million tonnes sulphuric acid per year, and 1 million NPK fertilizer per year. The factory will need yearly some 150,000 tonnes of ammonia, 800,000 tonnes of phosphate rock (imported from Jordan), and 270,000 tonnes of sulphur.

The investment cost is of about US$ 310 million.

Indonesia is the third biggest rice producer, after China and India, and its current fertilizer consumption in Indonesia is of about 8 million tonnes and has been forecasted to increase to 12 million tonnes in 2015. Jordan Phosphate Mine Co. is the sixth-largest global phosphate rock producer (up to seven million tonnes a year) and the second-largest exporter.

Russia: Acron Group 2010 Operating Results

February 17, 2011 at 09:46 (Fertilizers)

In 2010 the Acron Groups total commercial output was up 8.3% year-on-year to 5,754 thousand tonnes. Commercial output of ammonia and mineral fertilizers rose 7.5% year-on-year to 4,618 thousand tonnes. The consolidated ammonia output increased 2.4% and nitrogen fertilizers output rose 2.7% year-on-year. Due to strong demand for liquid fertilizers, Acron boosted its UAN production output 61.7%. Ammonia nitrate production was down 10.9% due to an overhaul of the ammonia unit at Dorogobuzh facilities and redistribution of Acrons capacity utilization in favor of UAN and complex fertilizers.

In 2010 global demand for complex fertilizers fully recovered, and the Groups consolidated output rose 15.7% in this segment. Due to high demand for complex fertilisers in China , Hongri Acron increased NPK production 57% to 691 thousand tonnes. Acrons commercial output of complex fertilizers was up 8.9% to 1,120 thousand tonnes, and Dorogobuzh reduced its NPK output 2.4% to 602 thousand tonnes.

China: Migao to Construct 100,000 tpa Specialty Fertilizer Plant

February 17, 2011 at 09:43 (Fertilizers, Potash Fertilizers)

Migao Corporation, a leading producer of specialty potash fertilizers for the Chinese market, announced that it will be constructing a new 100,000 tonne per year specialty compound fertilizer production facility at a new location in Zunyi, Guizhou Province. It will be built in two modules with the initial 50,000 tonnes module scheduled for completion by the end of 2011. Migao has an existing 100,000 tonne specialty compound fertilizer facility operating at full capacity at its Sichuan location.

Migao is currently producing at full capacity, 320,000 tonnes of its two core potash-based fertilizers. With the addition of a 40,000 tonne potassium nitrate 50/50 joint venture with SQM, a new 40,000 tonne potassium sulphate facility near Shanghai in early 2011, and a 40,000 tonne potassium sulphate expansion at Changchun Migao later this year, Migao will have net production capacity of 420,000 tonnes. This figure does not include the co-products ammonium chloride or hydrochloric acid nor does it include 200,000 tonnes of specialty compound fertilizer produced annually at Sichuan Migao and Zunyi Migao.

Canada: Compass acquires Big Quill SOP maker

February 17, 2011 at 09:42 (Fertilizers, Potash Fertilizers)

Sulphate of potash producer Compass Minerals International, Inc. has announced that it had completed an all cash purchase of Canadian leading SOP producer Big Quill Resources for US$56.3 million. Big Quill makes “high-purity” SOP for nutrients used by crop and turf growers, as well as for non-agricultural specialty applications. The Company’s Wynyard site, in Saskatchewan, which can process up to 40,000 short tons per year, produces much of its SOP by extracting naturally-occurring sulphate from the brine of Big Quill Lake and combining it with potassium chloride. Big Quill sources its potassium chloride through a “very long-term, advantaged supply agreement. Compass expects the acquisition to be “immediately accretive”. In addition, they plan to expand Big Quill’s production and sales of high-value specialty products over time. The Kansas City based Compass is already a producer of “organic-approved” SOP, which it markets to crop, fruit, vegetable and tree nut growers in the Americas and Pacific Rim. According to Compass, Big Quill’s 2010 revenues are expected to be about $23 million with EBITDA of some $7 million; last year they sold some 35,000 short tonnes.